25 to 4000 GPM

US Patent #9962631

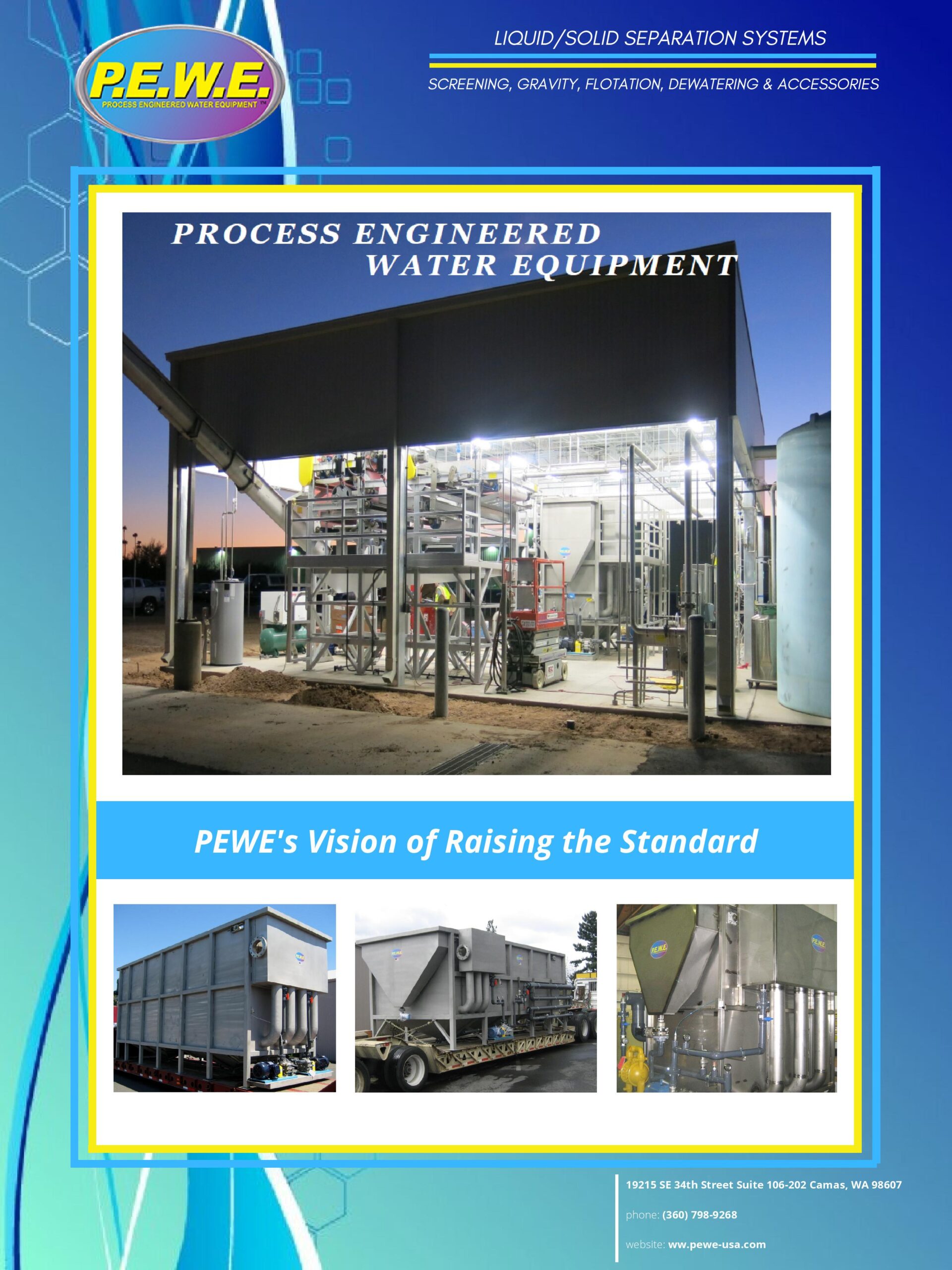

PEWE DAF Innovative Quality

The unique dissolved air flotation technology built into each T²-MAX® DAF system maximizes TSS removal while minimizing chemistry usage and sludge production. The chassis and vessel are constructed of AISI 304SS. the T²-MAX® features a traditional open style, ParaLam Weir® system, integrated pipe flocculator and Rogue MAX RGT® aeration. Additionally, the unit operates under the precision of the PEWE Command Control® automated panel.

PEWE products and systems are designed in-house and produced under tight quality control. PEWE offers products worldwide to the food, petrochemical, pharma, metal, electronic, and other industries along with the municipal market.

PEWE Aeration Technology

The heart behind a PEWE DAF’s aeration technology is the Rogue MAX RGT® pump. The regenerative turbine design creates the specific conditions necessary for dissolving air efficiently. Coupled with a PEWE DAF, this super air saturated water releases uniform 20-30 micron bubbles into the flotation system and effectively floats fine suspended solids.

Quality Materials, Premium Craftsmanship

The PEWE T²-MAX® TM DAF design encompasses the full array of newly advanced technological innovations.

- Dynamic Hydraulic Flow

- Traditional Open System

- ParaLam Weir® Water Extraction

- Rogue MAX RGT® Turbine Aeration

- Command Control® Panel

T²-MAX® System Specifications

Units: English or Metric

| Model | GPM | Footprint (ft) |

|---|---|---|

| All models designed 5000 ppm TSS avg @ 70F. | ||

| TM-25 | 25 | 6 x 11 x 6 |

| TM-50 | 50 | 7 x 13 x 6 |

| TM-75 | 75 | 7 x 18 x 6 |

| TM-125 | 125 | 9 x 19 x 9 |

| TM-250 | 250 | 12 x 24 x 9 |

| TM-500 | 500 | 13 x 31 x 11 |

| TM-750 | 750 | 13 x 37 x 12 |

| TM-1000 | 1200 | 13 x 44 x 12 |

| Model | M³/hr | Footprint (m) |

|---|---|---|

| All models designed 5000 ppm TSS avg @ 21C. | ||

| TM-25 | 5.7 | 1.8 x 3.4 x 1.8 |

| TM-50 | 12 | 2.1 x 4.0 x 1.8 |

| TM-75 | 23 | 2.1 x 5.5 x 1.8 |

| TM-125 | 40 | 2.7 x 5.8 x 2.7 |

| TM-250 | 57 | 3.7 x 7.3 x 2.7 |

| TM-500 | 113 | 4.0 x 9.5 x 3.4 |

| TM-750 | 170 | 4.0 x 11.3 x 3.7 |

| TM-1000 | 272 | 4.0 x 13.4 x 3.7 |