Channel Screen Systems

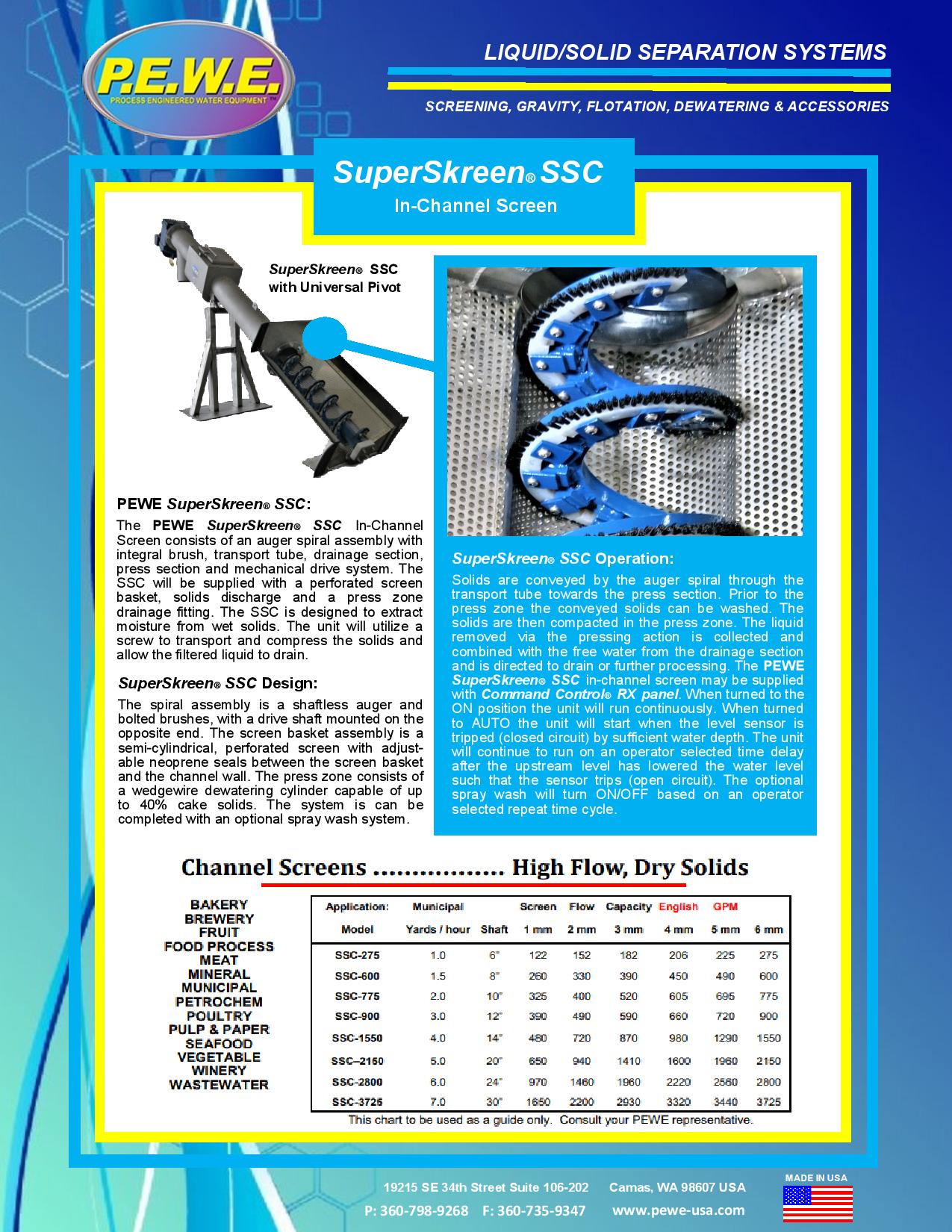

PEWE SuperSkreen® SSC

The PEWE SuperSkreen® SSC In-Channel Screen consists of an auger spiral assembly with integral brush, transport tube, drainage section, press section and mechanical drive system. The SSC will be supplied with a perforated screen basket, solids discharge and a press zone drainage fitting. The SSC is designed to extract moisture from wet solids. The unit will utilize a screw to transport and compress the solids and allow the filtered liquid to drain.

SuperSkreen® SSC Design

The spiral assembly is a shaftless auger and bolted brushes, with a drive shaft mounted on the opposite end. The screen basket assembly of this screen water treatment equipment is a semi-cylindrical, perforated screen basket with adjustable neoprene seals between the screen basket and the channel. The press zone consists of a wedgewire dewatering cylinder capable of up to 40% cake solids. The system is complete with a spray wash system.

SuperSkreen® SSC Operation

Solids are conveyed by the auger spiral through the transport tube towards the press section. Prior to the press zone the conveyed solids can be washed. The solids are then compacted in the press zone. The liquid removed via the pressing action is collected and combined with the free water from the drainage section and is directed to drain or further processing. The PEWE SuperSkreen® SSC in-channel screen may be supplied with Command Control® RX panel. When turned to the ON position the unit will run continuously. When turned to AUTO the unit will start when the level sensor is tripped (closed circuit) by sufficient water depth. The unit will continue to run on an operator selected time delay after the upstream level has lowered the water level such that the sensor trips (open circuit). The optional spray wash will turn ON/OFF based on an operator selected repeat time cycle.

Contact us today, and we’ll be happy to address your questions regarding our various screen water treatment equipment and products.

Channel Screens — High Flow, Dry Solids

- BAKERY

- BREWERY

- FRUIT

- FOOD PROCESS

- MEAT

- MINERAL

- MUNICIPAL

- PETROCHEM

- POULTRY

- PULP & PAPER

- SEAFOOD

- VEGETABLE

- WINERY

- WASTEWATER

| Application: | Municipal | Screen | Flow | Capacity | English or Metric | GPM | ||

|---|---|---|---|---|---|---|---|---|

| Model | Yards / hour | Shaft | 1 mm | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| This chart to be used as a guide only. Consult your PEWE representative. | ||||||||

| SSC-275 | 1.0 | 6” | 122 | 152 | 182 | 206 | 225 | 275 |

| SSC-600 | 1.5 | 8” | 260 | 330 | 390 | 450 | 490 | 600 |

| SSC-775 | 2.0 | 10” | 325 | 400 | 520 | 605 | 695 | 775 |

| SSC-900 | 3.0 | 12” | 390 | 490 | 590 | 660 | 720 | 900 |

| SSC-1550 | 4.0 | 14” | 480 | 720 | 870 | 980 | 1290 | 1550 |

| SSC-2150 | 5.0 | 20” | 650 | 940 | 1410 | 1600 | 1960 | 2150 |

| SSC-2800 | 6.0 | 24” | 970 | 1460 | 1960 | 2220 | 2560 | 2800 |

| SSC-3725 | 7.0 | 30” | 1650 | 2200 | 2930 | 3320 | 3440 | 3725 |

| Application: | Municipal | Screen | Flow | Capacity | English or Metric | LPM | ||

|---|---|---|---|---|---|---|---|---|

| Model | Meter / hour | Shaft | 1 mm | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| This chart to be used as a guide only. Consult your PEWE representative. | ||||||||

| SSC-275 | 0.76 | 152mm | 462 | 575 | 689 | 780 | 852 | 1040 |

| SSC-600 | 1.14 | 203mm | 985 | 1249 | 1476 | 1703 | 1854 | 2271 |

| SSC-775 | 1.6 | 254mm | 1230 | 1514 | 1968 | 2290 | 2630 | 2933 |

| SSC-900 | 2.3 | 305mm | 1476 | 1854 | 2333 | 2498 | 2725 | 3406 |

| SSC-1550 | 3.0 | 355mm | 1816 | 2725 | 3293 | 3709 | 4883 | 5867 |

| SSC-2150 | 3.8 | 508mm | 2460 | 3558 | 5337 | 6056 | 7420 | 8138 |

| SSC-2800 | 4.6 | 610mm | 3672 | 5526 | 7413 | 8403 | 9690 | 10,600 |

| SSC-3725 | 7.0 | 762mm | 6245 | 8328 | 11091 | 12567 | 12832 | 14195 |