Truck Receiving Unit

PEWE DeWater® TRU Systems

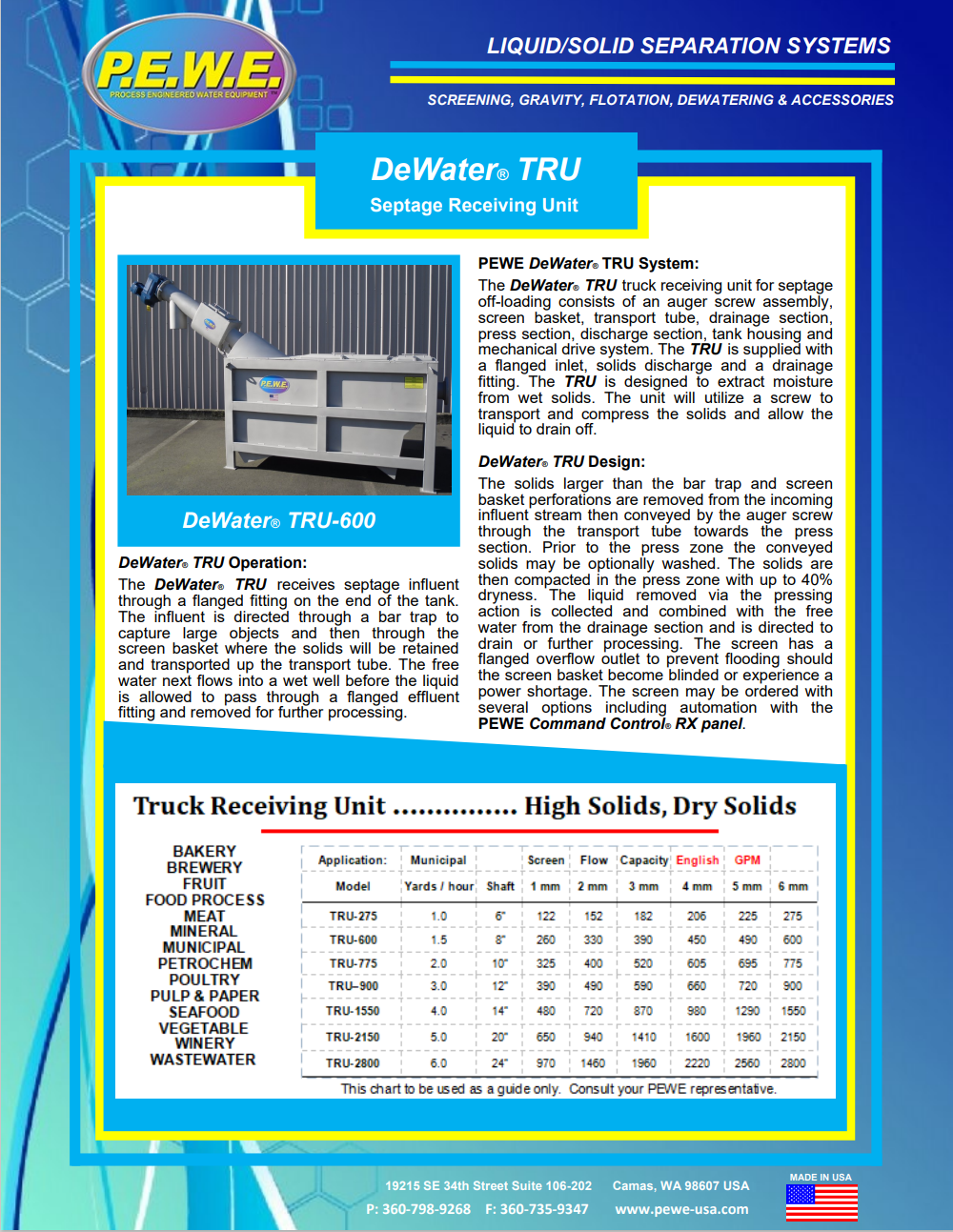

The TRU is designed to extract moisture from wet solids. The unit utilizes a screw to transport and compress the solids and allow the liquid to drain off. The PEWE DeWater® TRU Truck Receiving Unit consists of an auger screw assembly, screen basket, transport tube, drainage section, press section, discharge section, tank housing, and mechanical drive system. The TRU is supplied with a flanged inlet, solids discharge, and a drainage fitting.

DeWater® TRU Design

The PEWE DeWater® TRU Truck Receiving Unit receives influent through an influent flange on the end of the tank. The liquid stream will be directed through a bar trap and then through a screen basket where the larger solids will be retained and transported up the transport tube. The free water flows to a wet well before the liquid is allowed to pass out a flanged effluent fitting and is removed for further processing.

DeWater® TRU Operation

Large objects are trapped at the bars while the screen basket perforations remove solids from the influent stream. The solids are conveyed by the auger screw through the transport tube towards the press section. The conveyed solids may be jet washed with an optional fresh water feature. The solids are then compacted in the press zone with up to 40% dryness. The liquid removed via the pressing action is collected and combined with the free water from the drainage section and is directed to drain for further processing. The screen has a flanged overflow outlet to prevent flooding should the screen basket become blinded or experience a power shortage. The screen may be ordered with several options including PEWE Command Control® RX panel.

Truck Receiving Unit — High Solids, Dry Solids

- BAKERY

- BREWERY

- FRUIT

- FOOD PROCESS

- MEAT

- MINERAL

- MUNICIPAL

- PETROCHEM

- POULTRY

- PULP & PAPER

- SEAFOOD

- VEGETABLE

- WINERY

- WASTEWATER

| Application: | Municipal | Screen | Flow | Capacity | English or Metric | GPM | ||

|---|---|---|---|---|---|---|---|---|

| Model | Yards / hour | Shaft | 1 mm | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| This chart to be used as a guide only. Consult your PEWE representative. | ||||||||

| TRU-275 | 1.0 | 6” | 122 | 152 | 182 | 206 | 225 | 275 |

| TRU-600 | 1.5 | 8” | 260 | 330 | 390 | 450 | 490 | 600 |

| TRU-775 | 2.0 | 10” | 325 | 400 | 520 | 605 | 695 | 775 |

| TRU-900 | 3.0 | 12” | 390 | 490 | 590 | 660 | 720 | 900 |

| TRU-1550 | 4.0 | 16” | 480 | 720 | 870 | 980 | 1290 | 1550 |

| TRU-2150 | 5.0 | 20” | 650 | 940 | 1410 | 1600 | 1960 | 2150 |

| TRU-2800 | 6.0 | 24” | 970 | 1460 | 1960 | 2220 | 2560 | 2800 |

| Application: | Municipal | Screen | Flow | Capacity | English or Metric | LPM | ||

|---|---|---|---|---|---|---|---|---|

| Model | Meter / hour | Shaft | 1 mm | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| This chart to be used as a guide only. Consult your PEWE representative. | ||||||||

| TRU-275 | 0.76 | 152mm | 462 | 575 | 689 | 780 | 852 | 1040 |

| TRU-600 | 1.14 | 203mm | 985 | 1249 | 1476 | 1703 | 1854 | 2271 |

| TRU-775 | 1.6 | 254mm | 1230 | 1514 | 1968 | 2290 | 2630 | 2933 |

| TRU-900 | 2.3 | 305mm | 1476 | 1854 | 2333 | 2498 | 2725 | 3406 |

| TRU-1550 | 3.0 | 355mm | 1816 | 2725 | 3293 | 3709 | 4883 | 5867 |

| TRU-2150 | 3.8 | 508mm | 2460 | 3558 | 5337 | 6056 | 7420 | 8138 |

| TRU-2800 | 4.6 | 610mm | 3672 | 5526 | 7413 | 8403 | 9690 | 10,600 |