The Right Dewatering System

It is important to select the correct DeWater® System for your application. Solids dewatering is accomplished at various stages of the solid’s life cycle. An industrial solid’s life cycle typically starts with the receiving of raw materials and it goes through a process to maximize solids recovery. It does so through sedimentation of solid waste present in the water. These materials may be organic or inorganic, minute insoluble specs to large gross solids. They range from a highly liquified fluid to a near non-leachable cake.

Dewatering is necessary for a number of reasons: It reduces disposal costs, improves self-life stability, minimizes odors, and can prevent a valuable resource from going to waste. The poor disposal of wastewater pollutes various water sources leading to scarcity of this precious commodity. The only solution here is to reuse or recycle wastewater through a viable treatment process. PEWE is proud provide our clients with innovative process and wastewater treatment solutions with the full array of DeWater® Systems covering the varying needs of the market today.

DeWater® System Advantages

- Large Filtration Capacities

- Maximize Performance

- Sustainable Solids Feed Rates

- High Solids Capture

- Compact Footprint

- Reuse Wash Systems

- Heavy Duty Stainless Steel

- Ease of Maintenance

DeWater® TRU Systems

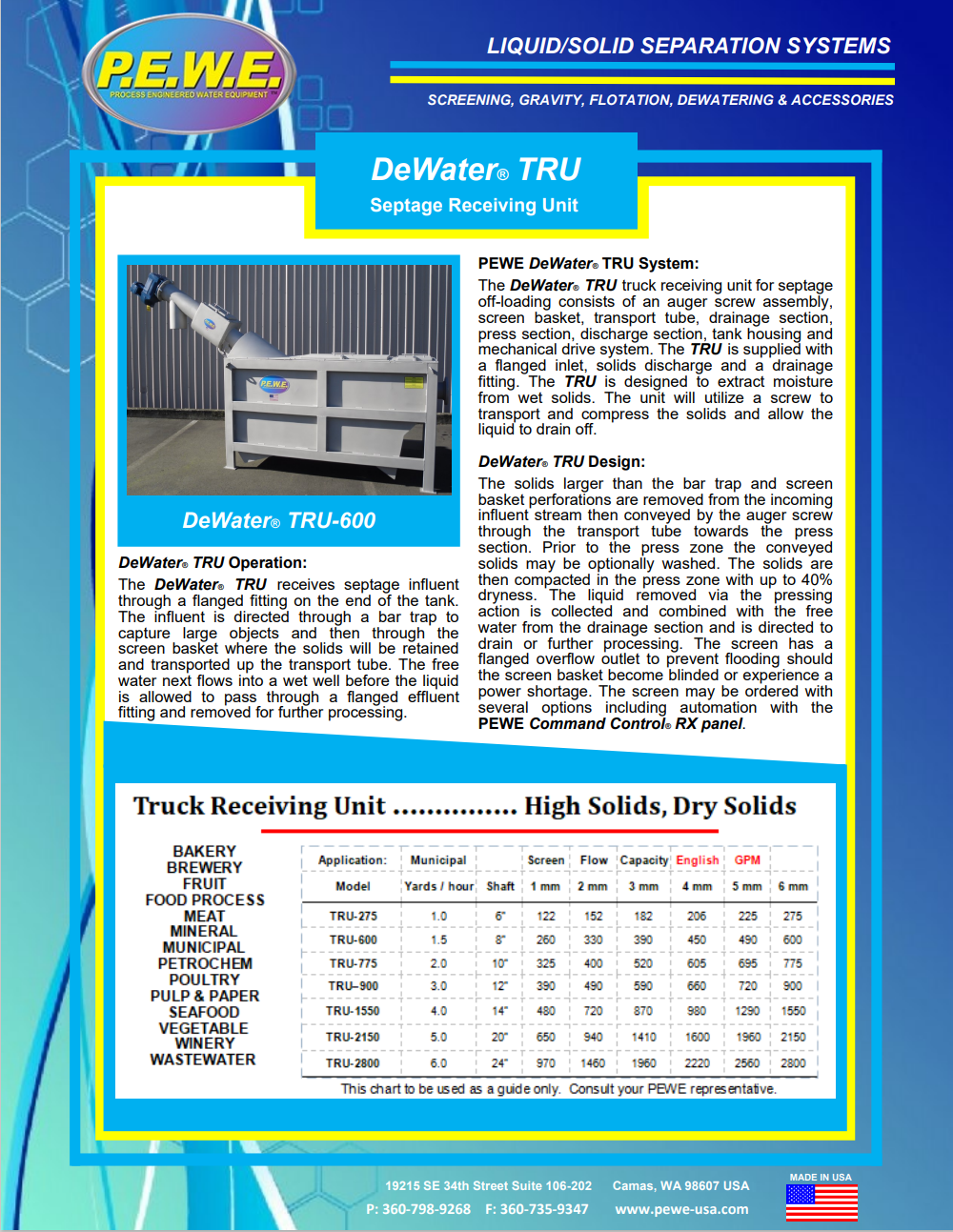

The PEWE DeWater® TRU Truck Receiving Unit is a rugged septage dump unit. The system receives influent from septage, vacuum or porta-potty trucks through an easy connect influent flange located on the front end of the tank. The liquid stream will be directed through a bar trap which collects objects larger than several inches in width. The influent then flows into a screen basket where the solids (which exceed the screen perforation size) will be retained and transported up the transport tube. The free water flows through the screen to a wet well before the liquid is allowed to pass out a flanged effluent fitting for further processing. The solids transported up the tube undergo further dewatering until reaching the compression zone. At the compression zone solids pack, are rinsed, and then shed to the discharge chute and removed for disposal.

DeWater® AC Systems

The core of PEWE’s screw technology behind the DeWater® AugerConveyor AC is its unique spiral design. Engineered after physical principals, our design creates prime conditions for conveying semi or solid material ranging from 10% to 65% total solids. These materials easily rise up the slick stainless steel and UHMW wear surface. The DeWater® AugerConveyer AC may be angled at a maximum of 25 degrees to assure complete solids discharge out the top mounted chute. These systems are sized generously to allow for 10, 20 and 30 cubic yard roll off dumpster to readily clear the discharge chute. Guard covers protect the auger.

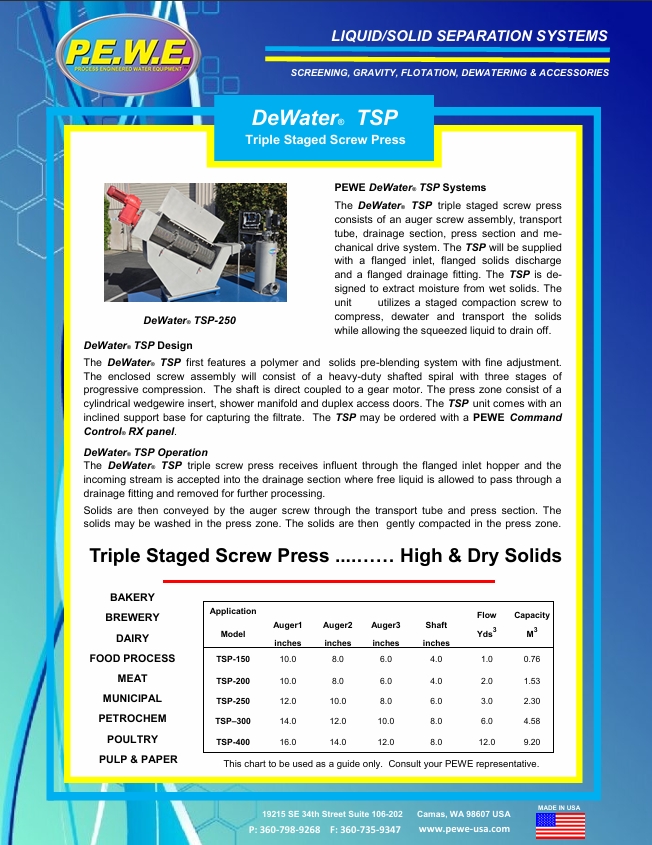

DeWater® TSP Systems

The DeWater® TSP triple staged screw press consists of an auger screw assembly, transport tube, drainage section, press section and mechanical drive system. The TSP will be supplied with a flanged inlet, flanged solids discharge and a flanged drainage fitting. The TSP is designed to extract moisture from wet solids. The unit utilizes a staged compaction screw to compress, dewater and transport the solids while allowing the squeezed liquid to drain off.

PEWE DeWater® Innovative Quality

PEWE has specialized in manufacturing premium quality dewatering equipment since entering the water treatment marketplace back in 2007. Additionally, we hold US Patents #8431022 and #9962631 for the design of our DAF water treatment equipment, as well as 21 registered trademarks. PEWE is proud to offer our clients the full array of DeWater® Systems covering the varying needs of the market today. And PEWE high quality products and systems are designed in-house and produced under tight control.

The entire PEWE liquid/solid separation equipment product portfolio includes wastewater screens, plate settler clarifiers, oil/water separators, sludge solids dewatering filter presses, biological MBBR and control automation. PEWE offers products worldwide to the food, petrochemical, pharma, metal, electronic, and other industries along with the municipal market. If you’d like to learn more about our selection of DeWater® Systems, our other wastewater equipment, or to discuss your particular wastewater needs, contact us. One of our experienced team members will be happy to help you.