DeWater® CSP

Compactor Screw Press

PEWE DeWater® CSP Systems

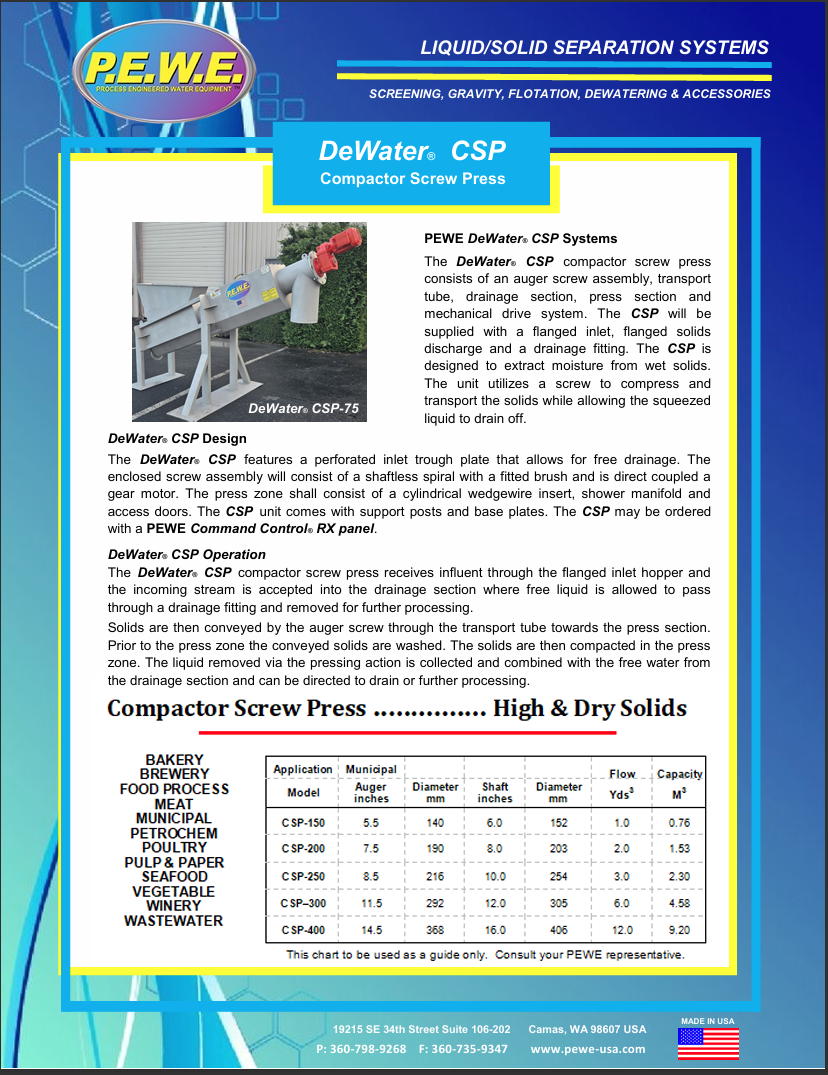

The PEWE DeWater® CSP Compactor Screw Press consists of an auger screw assembly, transport tube, drainage section, press section, and mechanical drive system. It is supplied with a flanged inlet, flanged solids discharge, and a drainage fitting. The CSP is designed to extract moisture from wet solids. It accomplishes this by utilizing the auger screw to transport and compress the solids and allow the liquid to drain off.

DeWater® CSP Design

The PEWE DeWater® CSP features a perforated inlet trough plate that allows for free drainage. The enclosed screw assembly consists of a shaftless spiral with a fitted brush and is direct coupled a gear motor. The press zone consists of a cylindrical wedgewire insert, shower manifold, and access doors. The CSP unit comes with support posts and base plates. The CSP may be ordered with a PEWE Command Control® RX panel.

DeWater® CSP Operation

The PEWE DeWater® CSP Compactor Screw Press receives influent through the flanged inlet hopper and the incoming stream is accepted into the drainage section. There, free liquid is allowed to pass through a drainage fitting and is removed for further processing.

Solids are then conveyed by the auger screw through the transport tube towards the press section. Prior to the press zone the conveyed solids are washed. The solids are then compacted in the press zone. The liquid removed via the pressing action is collected and combined with the free water from the drainage section and can be directed to drain or further processing.

Compactor Screw Press — High & Dry Solids

- BAKERY

- BREWERY

- FRUIT

- FOOD PROCESS

- MEAT

- MINERAL

- MUNICIPAL

- PETROCHEM

- POULTRY

- PULP & PAPER

- SEAFOOD

- VEGETABLE

- WINERY

- WASTEWATER

| Application: | Municipal | Flow | Capacity | |||

|---|---|---|---|---|---|---|

| Model | Auger inches |

Diameter mm |

Shaft inches |

Diameter mm |

Yds³ | M³ |

| This chart to be used as a guide only. Consult your PEWE representative. | ||||||

| CSP-150 | 5.5 | 140 | 6.0 | 152 | 1.0 | 0.76 |

| CSP-200 | 7.5 | 190 | 8.0 | 203 | 2.0 | 1.53 |

| CSP-250 | 8.5 | 216 | 10.0 | 254 | 3.0 | 2.30 |

| CSP-300 | 11.5 | 292 | 12.0 | 305 | 6.0 | 4.58 |

| CSP-400 | 14.5 | 368 | 16.0 | 406 | 12.0 | 9.20 |