How the PEWE ASO® Bio-Carrier Moving Bed BioReactor Works

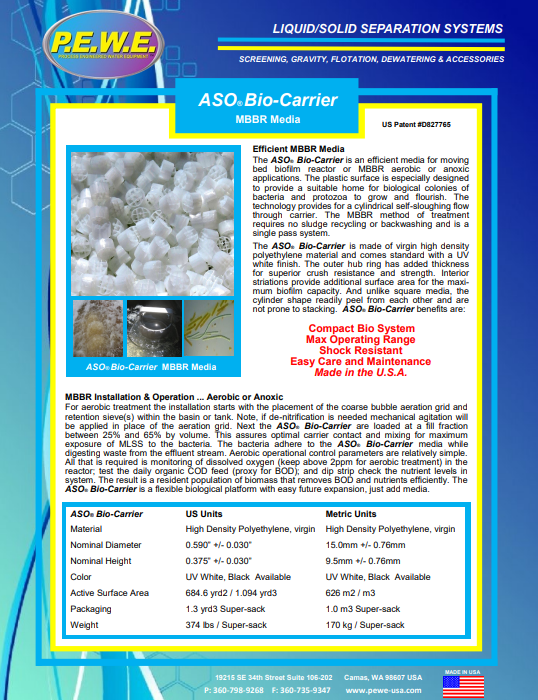

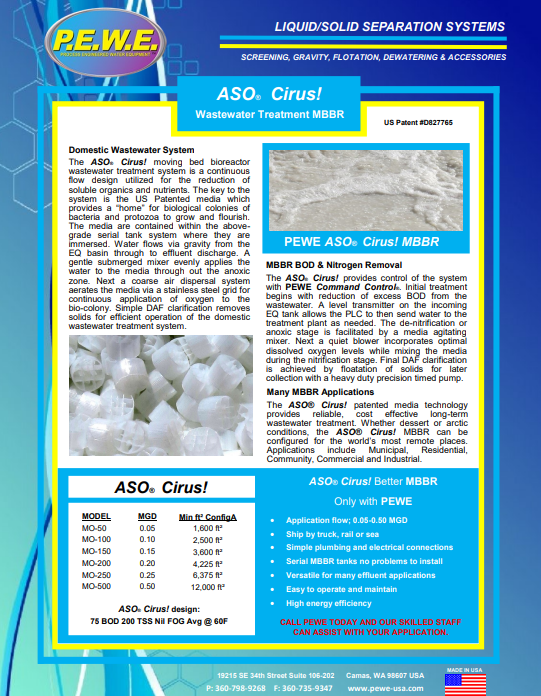

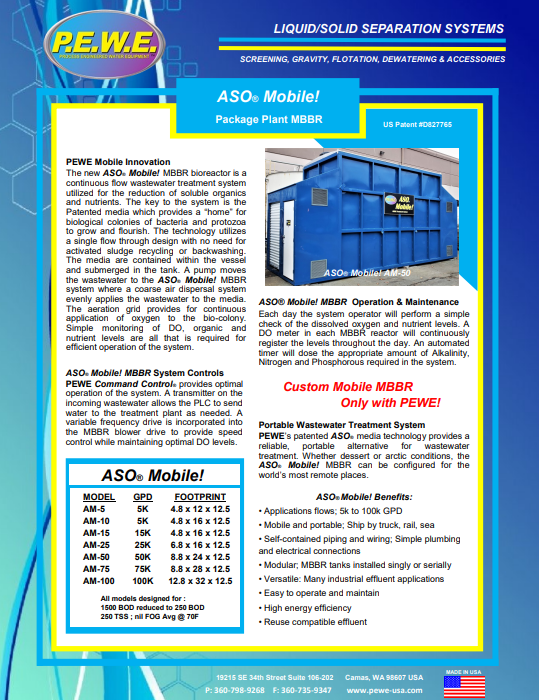

The ASO® Bio-Carrier Moving Bed BioReactor (MBBR) is a standalone wastewater treatment system used for the reduction of soluble organics and nutrients. The key to the system is the PEWE US Patented (#D827765) plastic media which provides a suitable home for biological colonies of bacteria and protozoa to grow and flourish. The ASO® Bio-Carrier Media Moving Bed Biofilm Reactor technology is a straightforward flow through design with no sludge recycling or backwashing is necessary. The media are contained within the vessel(s) and mixing energy is applied via coarse bubble aeration, typically for BOD/COD reduction. If de-nitrification is needed, mechanical agitation will be applied in place of aeration creating the necessary anoxic environment. The ASO® Bio-Carrier Moving Bed BioReactor is a flexible biological platform with easy future expansion—just add media.

ASO® Bio-Carrier MBBR Advantages

- Compact Biological System

- BOD & COD Removal

- Nutrient Removal

- Modular Durable Design

- Max Operating Range

- Shock Resistant

- Low “Washout” Versus Others

- Easy Care and Maintenance

- 100% Virgin Materials, US Manufactured

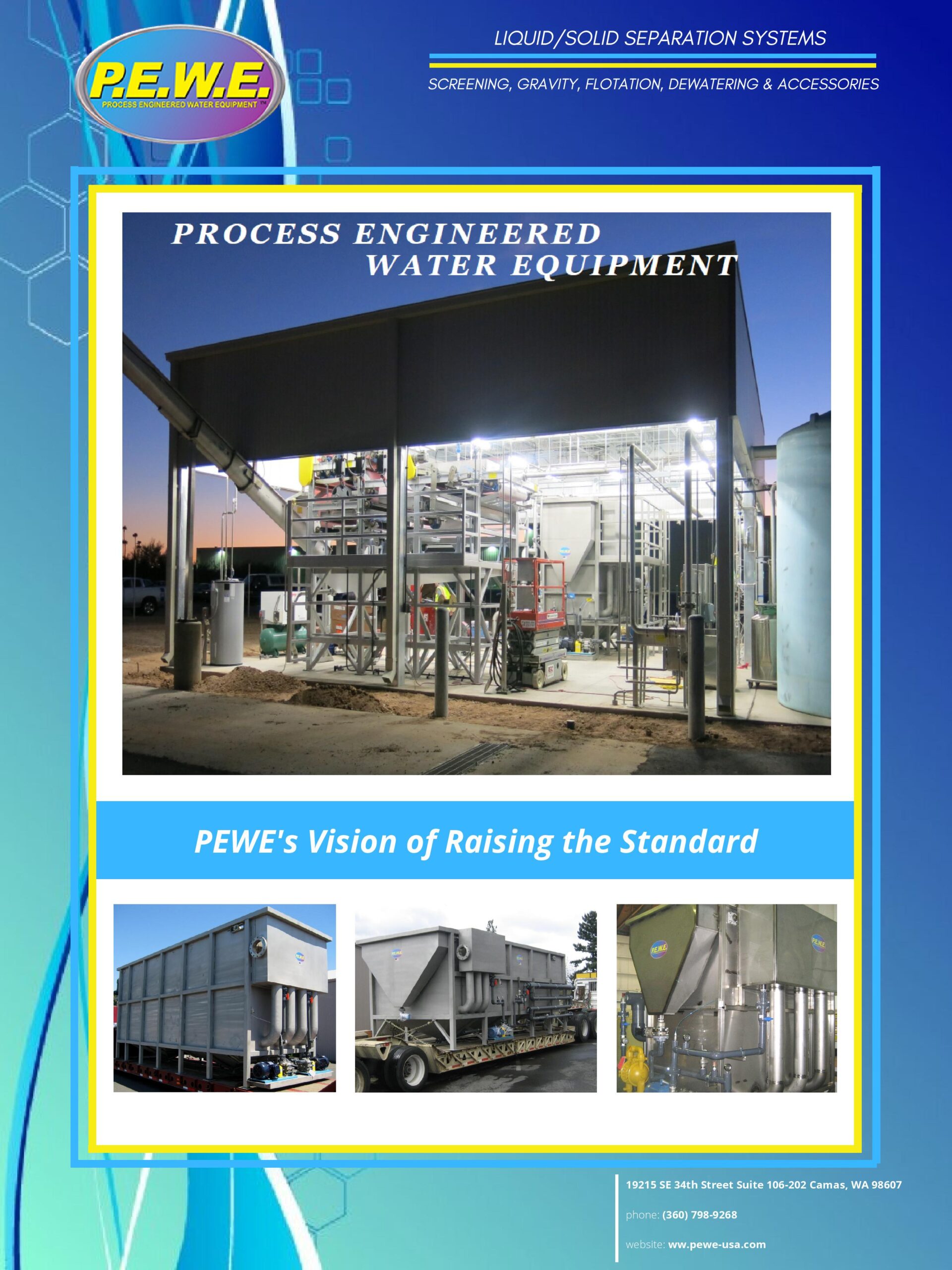

PEWE ASO® Bio-Carrier MBBR Package Plant- Aerobic Treatment System for Soluble Organics

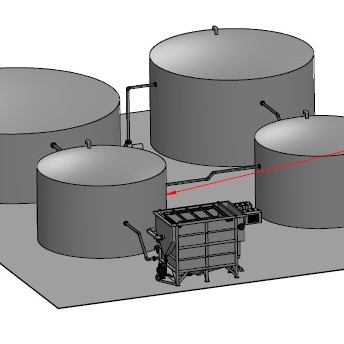

A complete integrated PEWE aerobic biological treatment system or ASO® Bio-Carrier MBBR water treatment system is a great tool for reducing soluble organics, BOD and COD. The package plant system typically consists of an initial SuperSkreen®, an equalization/pH tank, the ASO® Bio-Carrier MBBR media contained within one or more vessels with redundant blowers, PolyAccu Dose® nutrient and polymer feed station. Clients have a choice of Dissolved Air Flotation between the HD2XLRator®, Nx2JEM®, T2-MAX®, Poly-E2® or the new Dueler® DAF unit for final clarification. The entire MBBR water treatment package is controlled with a state-of-the-art Command Control® automation panel with color touch-screen operator interface. This flexible design feature allows for a small footprint at new installations or upgrades to existing systems.

ASO® Bio-Carrier MBBR system operational control parameters are relatively simple. All that is required is monitoring of DO in the reactor (keep above 2ppm) via continuous automated control, testing the daily organic COD feed (proxy for BOD), and checking the nutrient levels in the system via dip strip. The several installation options ensure maximum exposure of MLSS to the media. The bacteria adhere to the media while digesting waste from the plant effluent stream. The result is a resident population of biomass that removes BOD and COD efficiently. Consult your PEWE Client Systems Engineer with your specific biological needs.

PEWE ASO® Bio-Carrier MBBR & Innovative Quality

PEWE has specialized in manufacturing quality process engineered water and wastewater equipment since entering the water treatment marketplace back in 2007. The ASO® Bio-Carrier is registered under US Patented #D827765 by PEWE. Additionally, we hold US Patents #8431022 and #9962631 for the design of our DAF water treatment equipment, as well as 21 registered trademarks. PEWE is proud to offer our clients the full array of process, water and wastewater screen equipment to the industrial and municipal market today. PEWE’s high quality products and systems are designed in-house and produced under tight control.

The entire PEWE liquid/solid separation equipment inventory includes wastewater screens, plate settler clarifiers, oil/water separators, sludge solids dewater filter presses, biological MBBR and control automation. PEWE offers products worldwide to the food, petrochemical, pharma, metal, electronic, and other industries along with the municipal market. If you’d like to learn more about our selection of ASO® Bio-Carrier MBBR water treatment systems, our other wastewater equipment or to discuss your particular water treatment needs contact us. One of our experienced team members will be happy to help you.