How Oil Water Separation Works

Oil water separator systems work under the physical principal of density. Oil and many petroleum products have less density than water. In other words, they are lighter than water. This causes them float along the surface. This means that wastewater contaminated with oil may be separated mechanically through the application of Stoke’s Law. That is the rising velocity of a particle depends upon the particle’s size, density, and the viscosity of the water.

In practical terms this means creating the specific condition for capturing free oil along laminar collectors, agglomerating the oils into larger particles until their respective buoyancy floats them to the surface of the vessel where they may be collected. The treated wastewater is then discharged. Some oil water separators use gravity separation to disassociate oils from settle-able solids. These are referred to as multi-phase separators.

PEWE Industrial Oil/Water Separator Advantages

Clients benefit with many advantages using PEWE Oil/Water Separator systems. PEWE Oil/Water Separator models include the following unique design features:

PEWE OWS, OWS-PTM and OZ® Systems:

- Advanced stilling well influent entry for optimal laminar flow.

- Corrosion resistant AISI 304L stainless steel construction.

- Flanged influent, effluent and oil connections.

- Bottom discharge drain for easy rinse out.

- Adjustable integral oil capture reservoir.

- Adjustable effluent weir for maximum oil pool retention.

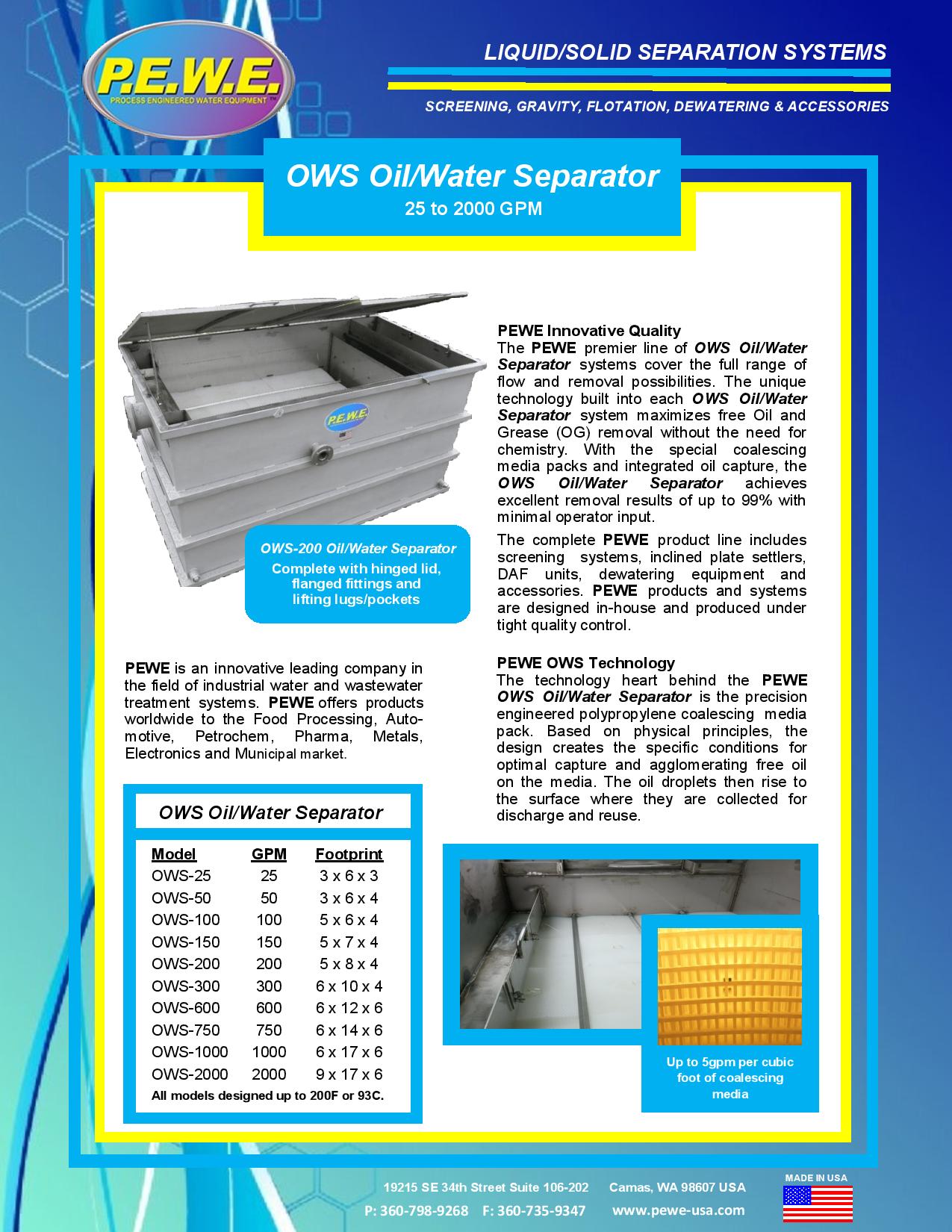

PEWE OWS Systems:

- Non-mechanical oil coalescing media.

- Designed for low TSS and low Settle-able solids oily water.

- Polypropylene maximum temperature 140*F.

- Compact flat bottom design.

- Dual cleanout ports, topside.

- Enclosure lid with handle and support.

- Optional flanged gas evacuation port.

PEWE OWS-PTM Systems:

- Multi Phase separator.

- Diamond PerfTM oil coalescing grid.

- Designed for mixed Settle-able solids oily water.

- Vessel, chassis and grid stainless steel construction.

- Cone bottom Settle-able solids collection.

- Stainless steel knife air actuated discharge valve(s).

- Air diaphragm solids removal pump.

- Optional enclosure lid with handle and support.

- Optional flanged gas evacuation port.

PEWE OZ® Systems:

- Multi Phase separator.

- Designed for mixed TSS and Settle-able solids oily water.

- Fully convertible to a complete DAF system.

- Integrated pipe flocculators for effective chemical addition.

- Safety recessed variable speed direct drive chain & flight for the oily sludge solids removal.

- Non-clogging air diaphragm pump oily solids removal.

- Enhanced anti-flex take-up frames.

- US Patented self-cleaning weir water management.

- Optional enclosure lid with handle and support.

- Optional flanged gas evacuation port.

PEWE Oil/Water Separator & Innovation

The PEWE premier line of industrial Oil/Water Separator systems by PEWE encompasses a wide range of flow and removal capabilities. The patented technology built into every Oil/Water Separator system maximizes the removal of insoluble oil and petroleum products. All PEWE Oil/Water Separators achieve excellent removal results with minimal operator input. PEWE has specialized in manufacturing premium Oil/Water Separator equipment since entering the water treatment marketplace back in 2007. We hold US Patents #8431022 and #9962631 for the design of our DAF water treatment equipment, as well as 21 registered trademarks. PEWE is proud to offer our clients an array of Oil/Water Separators covering the varying needs of the market today. PEWE high quality products and systems are designed in-house and produced under tight control.

The entire PEWE liquid/solid separation equipment product portfolio includes wastewater screens, DAF systems, plate settler clarifiers, sludge solids dewatering filter presses, biological MBBR and control automation. PEWE offers our products worldwide to the food, petrochemical, pharma, metal, electronic, and other industries along with the municipal market. If you’d like to learn more about our selection of Oil/Water Separator treatment systems, our other wastewater equipment, or to discuss your particular water treatment needs, contact us. One of our experienced team members will be happy to help you.