10 to 2000 GPM

PEWE Innovative Quality System

The PEWE premier line of OWS Oil/Water Separator systems cover the full range of flow and removal possibilities. The unique technology built into each OWS Oil/Water Separator system maximizes free Oil and Grease (OG) removal without the need for chemistry. With the special coalescing media packs and integrated oil capture, the OWS Oil/Water Separator achieves excellent removal results of up to 99% with minimal operator input.

The complete PEWE product line includes screening systems, inclined plate settlers, DAF units, dewatering equipment and accessories. PEWE products and systems are designed in-house and produced under tight quality control.

PEWE is an innovative leading company in the field of industrial water and wastewater treatment systems. PEWE offers products worldwide to the food, petrochemical, pharma, metal, electronic, and other industries along with the municipal market.

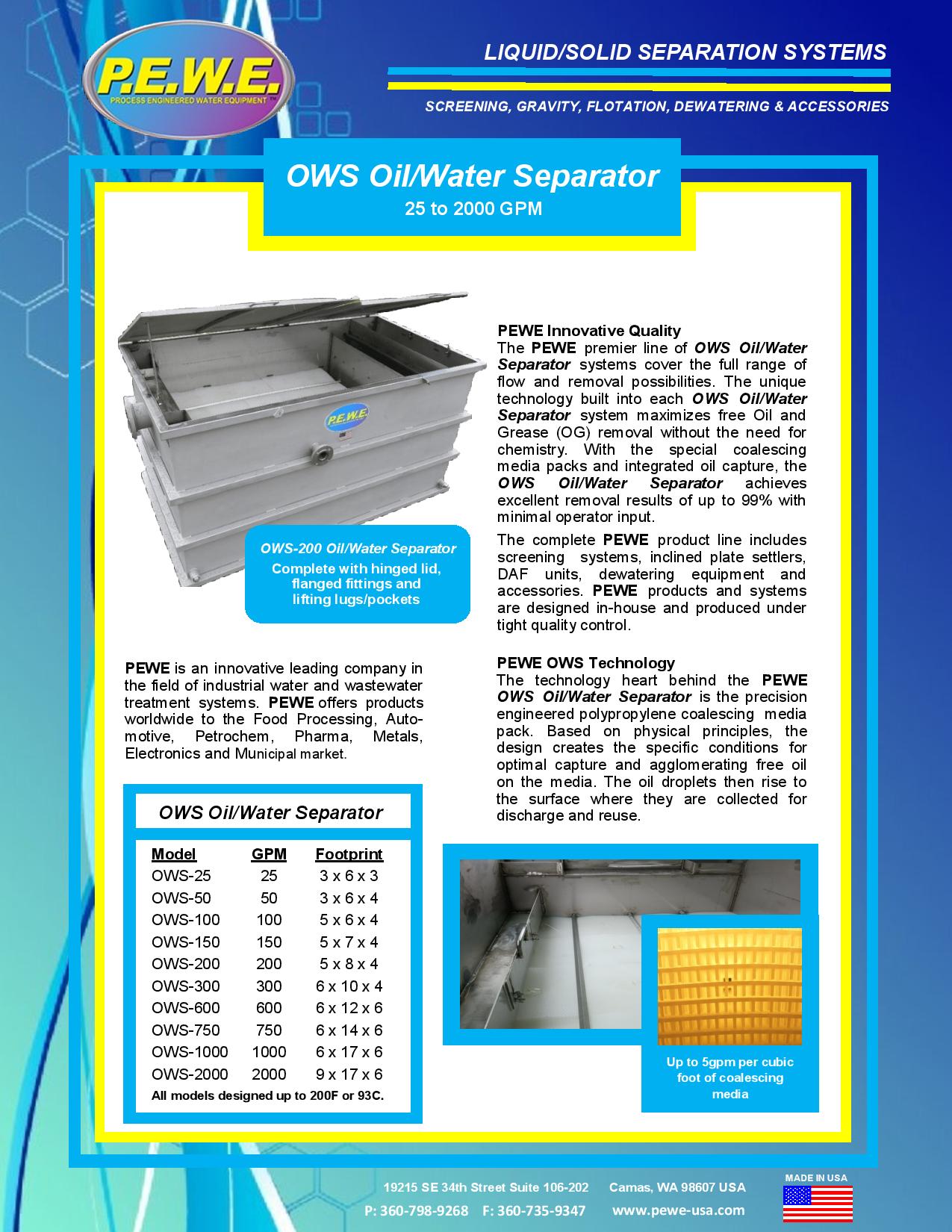

PEWE OWS Technology

The heart behind the PEWE OWS Oil/Water Separator’s coalescing technology is the precision engineered polypropylene coalescing media pack. Based on physical principles, the design creates the specific conditions for optimal capture and agglomeration of free oil on the media. The oil droplets then rise to the surface where they are collected for discharge and reuse.

PEWE Vessel & Chassis System

The OWS Oil/Water Separator vessel and chassis are available in both AISI 304 stainless steel or corrosion resistant carbon coated steel. All units come with hinged lids, 150lb flanged ports, bottom pocket framing and lifting lugs for easy positioning, hook-up and service access.

Don’t hesitate to contact us at your earliest convenience to learn more about PEWE’s OWS Oil/Water Separator systems and how they can benefit you. We are happy to discuss your water treatment system requirements with you and recommend a system that can address them as efficiently as possible.

OWS Oil/Water Separator

Units: English or Metric

| Model | GPM | Footprint (ft) |

|---|---|---|

| All models designed up to 200F or 93C. | ||

| OWS-25 | 25 | 3 x 6 x 3 |

| OWS-50 | 50 | 3 x 6 x 4 |

| OWS-100 | 100 | 5 x 6 x 4 |

| OWS-150 | 150 | 5 x 7 x 4 |

| OWS-200 | 200 | 5 x 8 x 4 |

| OWS-300 | 300 | 6 x 10 x 4 |

| OWS-600 | 600 | 6 x 12 x 6 |

| OWS-750 | 750 | 6 x 14 x 6 |

| OWS-1000 | 1000 | 6 x 17 x 6 |

| OWS-1500 | 1500 | 9 x 17 x 6 |

| Model | M³/hr | Footprint (m) |

|---|---|---|

| All models designed up to 200F or 93C. | ||

| OWS-25 | 5.7 | 0.9 x 1.8 x 0.9 |

| OWS-50 | 12 | 0.9 x 1.8 x 1.2 |

| OWS-100 | 23 | 1.5 x 1.8 x 1.2 |

| OWS-150 | 34 | 1.5 x 2.1 x 1.2 |

| OWS-200 | 45 | 1.5 x 2.4 x 1.2 |

| OWS-300 | 68 | 1.8 x 3.0 x 1.2 |

| OWS-600 | 113 | 1.8 x 3.7 x 1.8 |

| OWS-750 | 170 | 1.8 x 4.3 x 1.8 |

| OWS-1000 | 230 | 1.8 x 5.2 x 1.8 |

| OWS-2000 | 454 | 2.7 x 5.2 x 1.8 |